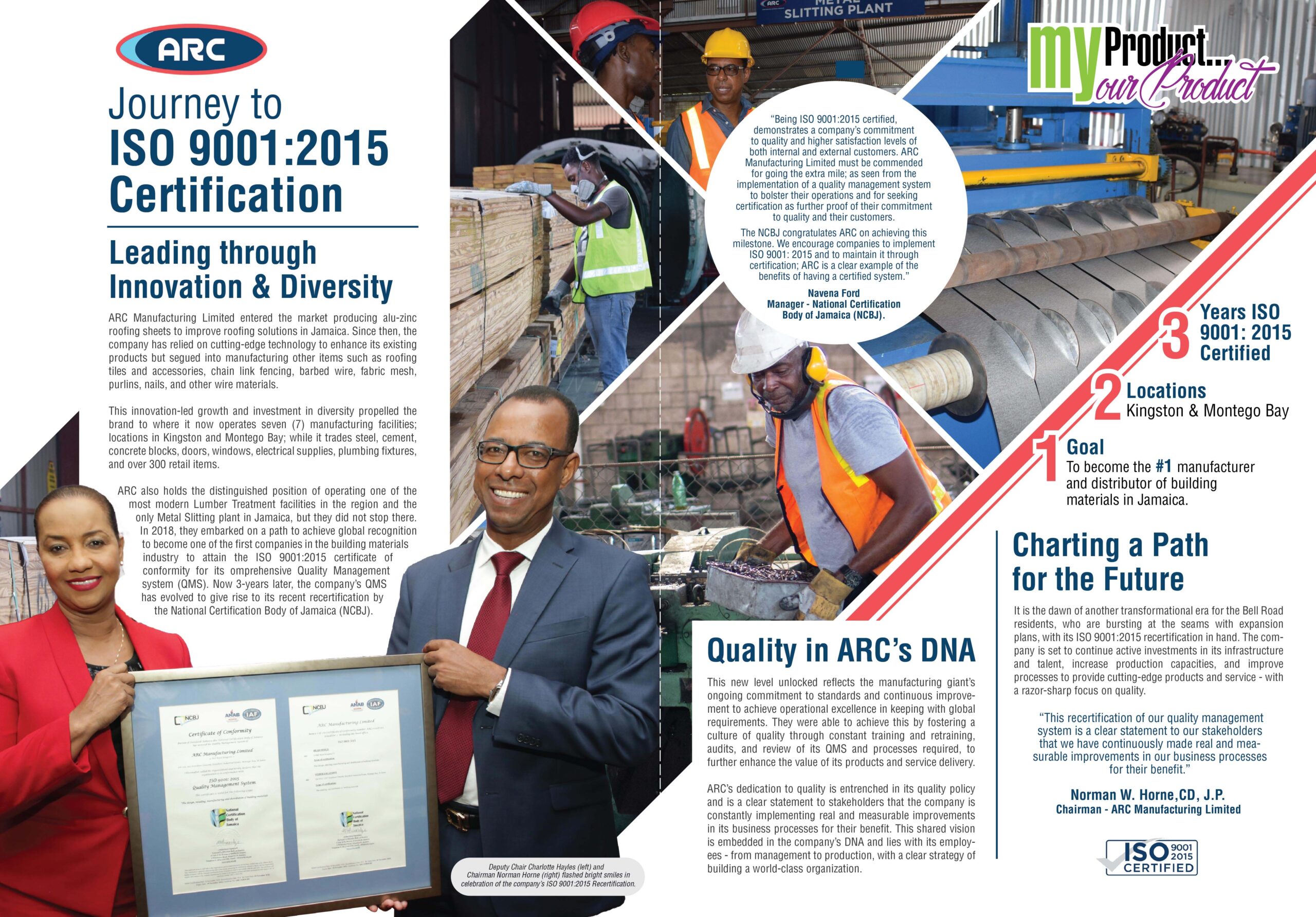

Construction materials company ARC Manufacturing Limited is converting one of the warehouses at its plant on Bell Road in Kingston into factory space prepares to venture into the manufacturing of steel hollow sections and metal pipes.

The two new plants to be developed will share a 30,000-square-foot space, will position the company as the sole manufacturer of hollow sections and metal pipes in Jamaica, and will ultimately give it the muscle it needs to carve market share away from imports, the company indicated this week.

At the core of ARC’s business is the importation of metals which are then processed into finished goods including wire nails, barbed wire, quarter wire, binding wire, fabric mesh, nails, chainlink fencing, tracks and studs, purlins, circular and industrial zinc, roofing tiles, hurricane straps, and other roofing products.

The 12-year-old company currently stands as the sole manufacturer of binding wire in Jamaica. Its distributed line includes all its manufactured products, as well as cement, concrete blocks, structural steel, rebars, merchant bars, plywood, hardboard, cement board, furniture ply, plumbing and electrical supplies, steel plates, paints, furniture lumber, among other retail items.

Outside of being the sole manufacturer of binding wire, the manufacturing giant also operates a lumber treatment plant, which is said to be one of the most modern in the region; as well as a metal slitting plant – the only of its kind in Jamaica.

The company markets its goods to businesses across varying sectors in Jamaica, as well as retails products from a store at its Bell Road plant. Offshore, it does business in the southern United States and Caricom markets, where, outside of Jamaican customers, it will first seek takers for its supplies of steel hollows and metal pipes.

“ARC’s approach to manufacturing is based on there being sufficient business in the domestic market to amortise our investment, as well as our ability to export our surpluses. Our research has confirmed that is sufficient demand for hollow sections and pipe in the domestic market and there are also opportunities,” Chairman of ARC Manufacturing, Norman Horne, told the Financial Gleaner, following a tour of the company’s near 18-acre complex by the Private Sector Organisation of Jamaica on Wednesday.

“In the Caribbean, Haiti does some level of conversion of hollow sections, but throughout Caricom there are no manufacturers who are doing this item. We are very excited about the Caribbean, particularly Caricom, and we are also very excited about the possibility of selling to the US given deteriorating relations between that country and China,” Horne said.

Steel hollows, which ARC will produce in square and round shapes, are used as structural material in construction. The section pipes are also used for everyday applications such as vehicle trailers, fences, scaffold and handrails. Metal pipes, on the other hand, are used to transport products, such as oil, gas and water, and are suitable for long-term installations.

ARC Manufacturing has already begun securing equipment for the new plants and will be engaging a specialist from Turkey to construct the facilities. The repurposed building is expected to be completed by the end of 2023.

“What we insist on when we bring technical persons from aboard is knowledge transfer; it’s part of the agreement we have. We have appointed a few persons to ensure that when they leave the knowledge stays,” Horne said.

Horne’s plan for the new production plants at Bell Road, which sits on the outskirts of Three Miles in Kingston, is the first of a two-part process to drive revenues up for the company.

The ISO9001:2105 certified company is also in the process of upgrading a 70,000-square foot warehouse on the property — a project that will eventually see the company switching out some of its manual forklift operations for an automated crane system, which will not only increase safety and accuracy in the warehouse, but will also give the company much more room to hold inventory due to a new form of stacking of heavy materials such as steel and timber.

Additionally, they will also install two bridge cranes in the ceiling of the warehouse, each of which has the capacity to lift 10 tonnes to a height of 20 feet, and cover 620 feet in length. The automated crane system, which will replace forklifts, offers the company a more effective way of stacking that utilises the building’s spacing, both in width and height, more efficiently. The crane’s hoist can rotate 360 degrees, which allows for packaging in parallel and perpendicular format, or put more simply, in a box format.

“At the moment, we are only utilising about 40 per cent of the warehouse space because the forklifts need space to traverse and you have to separate your products in a way that makes them accessible to forklifts,” said Horne.

“But with this modern crane we should be able to utilise 90 per cent of the space. What that means is that we will have more than enough room to transfer the materials being stored in the space that we intend to use for the two factories into the new warehouse,” Horne said.

ARC Manufacturing also stores materials at three locations owned and operated by an affiliated company called ARC Properties Limited. But those spaces will be freed up for lease to external parties, once the warehouse upgrade is completed. The improved facility will serve to bring goods stored outside of the plant indoors, while consolidating the internal steel warehouses.

“What I can say is that our aim is to do 1,400 tonnes of the products monthly,” he said.

While the manufacturing and distribution company is moving to automate some of its processes, Horne also said no jobs would be lost. The company is looking instead to add to its workforce.

“We are on a mission to modernise our business as part of our space management concept. The truth is that the way in which we are set up now, it may impact delivery times. So we are focusing on fixing that,” Horne said.

ARC Manufacturing employs about 350 workers full-time, many of whom are from the areas surrounding the Bell Road complex. On completion of the projects, the company expects to have north of 400 people on its payroll.

Published by the Jamaica Gleaner.