It is in times like these that Governments are put to the test. It is in times like these that Governments must take and implement extraordinary policy decisions and programmes to fast-track and realign the country on the road to development. The impact and implications of this COVID-19 are both seen and unseen and thus drastic times must call for drastic yet carefully balanced measures.

The hard truth

If we are one day past April 15, 2020, and the parishes of Kingston and St Andrew and the other 12 parishes are still under quarantine, having not joined St Catherine in “lockdown”, then Jamaica is seemingly on a pothole-riddled back road to COVID-19 recovery.

It is not a moot point that the human capital hub, now COVID-19 hotbed of Portmore is inextricably linked with both Kingston & St Andrew and Clarendon. As articulated by an employee: “Most of us who live in Portmore work and do everything else in Kingston. During the week we only sleep in Portmore.” Furthermore, the April 15, 2020 migration of persons from Portmore to Kingston & St Andrew buttresses the fact that not one of those three parishes can be divorced from the others. Furthermore, no parish within Jamaica’s 10,992 km2 is an island by itself. This is affirmed by the web of illness that COVID-19 is slowly weaving throughout our island and that which it has woven throughout the superpower states of the world.

The hard truth is that for the quickest socio-economic recovery, Jamaica would be better off sacrificing two weeks today as opposed to an indefinite period mere days after tomorrow. If we wait any longer to implement stringent social-distancing requirements, our best intentions may garner the worst results.

The misery index

We are a small country of approximately three million people. Population size will either be our fortune or prove fatal depending on the effectiveness of our national approach to COVID-19. The more the virus spreads and the longer the state of quarantine or lockdown lasts, then the greater the impact will be on the economy. We are all financially losing and will all continue to lose until COVID is cauterized.

The status quo today and in the short term for the average Jamaican indicates that the misery index is rising and may rise to epic proportions:

(1) Many Jamaicans are consuming, but not earning;

(2) Many Jamaicans have, or will exhaust all savings;

(3) Jamaicans with credit cards and great financial demands and responsibilities will max those cards out; and

(4) As a last resort, many Jamaicans have or will turn to borrowing at high exchange rates with the inability to repay in the short term.

The harsh realities that accompany the consumer burdened misery index will also have a severe impact upon the macroeconomy as follows:

(1) reduction in GDP;

(2) devaluation of the Jamaican dollar; and

(3) increase in inflation.

Presently, we are at risk of completely wiping out our micro, small and medium enterprises to include taxis, barbers, chefs, hairdressers, and small farmers who are all currently operating at a loss. Aside from the food industry and pharmaceuticals, many of us will not be able to survive a protracted collapse of the domestic economy.

The International Monetary Fund (IMF) has diagnosed that this “Great Lockdown” will be the “worst economic downturn since the Great Depression”. The IMF advises that, “The magnitude and speed of collapse in activity that has followed is unlike anything experienced in our lifetime.”

Acknowledging the variable factors and the uncertainty in the projections regarding the reopening of the global economy, the IMF has already had requests for emergency financing from more than 90 countries to date. The IMF has committed US$1 trillion in lending for countries economically affected by the COVID-19 pandemic.

Though previously confident that our net international reserves of over US$3 billion would have been able to cushion the COVID-19 blow, our minister of finance has done the right thing by turning back to the IMF for much-needed financial support. However, with the sudden and premature closure of the compassionate grant programme, it is now incumbent upon the Government to provide the citizenry with firm assurance that there is not only a safety net, but also an implementation plan in place to provide adequate social security for the protection of the poorest and most vulnerable. The Government has likely not forgotten: “If it takes cash to care, it also takes caring to achieve even in the face of penury” (Edward Seaga).

Immediately: BPO lockdown

The numbers speak for themselves without need for further comment. It is said that the call centre is now the national epicentre of COVID-19, and the most prevalent view is that the longer the call centres are open the more rampant the spread of COVID-19 will be islandwide. With the best of economic intentions, it is better to sacrifice two weeks now as opposed to 12 months later. The safeguarding of the lives of the Jamaican people should always be our primary focus. We can restart the economy, but we cannot revive those who we have lost to COVID-19. Unlike the tourism industry, which has succumbed to COVID’s economic demise, the Business Process Outsource (BPO) industry like most others would not be at a complete standstill but would pause to allow for the eradication of COVID-19 as opposed to its further spread.

The Jamaican people are starting to question whether or not there is a motive for keeping the BPO sector fully operational during this time. The argument is that one COVID-19 case merited the lockdown of Bull Bay. A few COVID-19 cases merited the lockdown of Cornpiece. However, scores of COVID-19 cases have not merited the closure of the BPO sector. Only the Government can speak to this.

Next 30 days: Private and increased testing

To date, and with some success, the country’s approach has been tracing, tracking, isolation and testing. However, based on the increased COVID-19 numbers, we must take a more robust approach to identify all persons who have contracted the virus and place them all in isolation. Almost all of the countries with the greatest COVID-19 combat success were not only early into lockdown but also began robust testing at the beginning of the spread. It is clear that our rate and methodology of testing is not only slow, but is also not widespread enough.

The organisational skills which are utilised heavily by politicians to garner votes and win elections should be put aggressively to use to combat COVID-19. For example, to increase testing, strategically placed polling stations could be converted to testing stations. This would not only make testing more accessible and encourage voluntary testing for symptomatic citizens, but it would also give the Government a more precise geographic picture of the infected and uninfected communities.

We have learned from the dengue experience that in the tracking of viral outbreaks, the Government cannot do it alone. For example, in June 2019 the country was told categorically that there was no dengue outbreak. However, by October 2019, it was reported that there had been 88 dengue-related deaths, almost doubling the deaths related to the disease in the preceding year. The Government in leading the COVID-19 battle seems to wish to have centralised testing and centralised testing only. This was the same approach taken with dengue decades ago. Nevertheless, it was soon discovered that private testing only strengthened the Government’s initiative to diagnose, test, cure, and accurately report.

Rapid test kits are available on the international market. The Government should therefore approve the private import of said tests and encourage private doctors who are so willing to procure rapid test kits, test, and report the results as happens today with dengue.

Compassionate policy appeal

There is a view that more humanity and compassion is needed by the citizenry as we combat covid-19. Expectations of Government intervention are extremely high and in the field of agriculture and basic services, particularly electricity there have been conversations which call for a compassionate policy appeal to be made on behalf of the Jamaican people:

(1) Electricity Disconnection: Many consumers who are unable to earn are concerned that their electricity either has or will be disconnected due to non-payment. This may well become a reality for many of us. It would be prudent for the Government to make an appeal to the Jamaica Public Service in an attempt to negotiate payment plans and an extension of service for those who will or may be struggling to pay their electricity bills. We do not wish those who have no earnings to be left in the dark indefinitely.

(2) Agriculture: The disastrous impact that COVID-19 has had on the agricultural sector has been highly publicised and the Government has made a marked effort to intervene. However, a blueprint plan should be shared with the public since the public will have to participate in these efforts by consuming the excess produce as opposed to disposing same. It would be savvy if the Government identified all cold storage points throughout the island, identified all areas where there would likely be real demand and supply and thereafter route supply to demand in an organised and consumer friendly fashion.

We are in this together

With no section of society unscathed, COVID-19 is an indiscriminate virus that suffers no fools. We are all in this together. It is therefore our patriotic duty to educate, participate in the discourse, and be a part of solutions on the road to COVID-19 recovery.

It is time to lock down all 14 parishes for at least two weeks and clean the country of COVID-19. This is not a time to wait and play catch-up. Perhaps Murphy’s Law, “If it can happen, it will,” may be a guiding principle for how we should proceed. For a brighter tomorrow, we must sacrifice today.

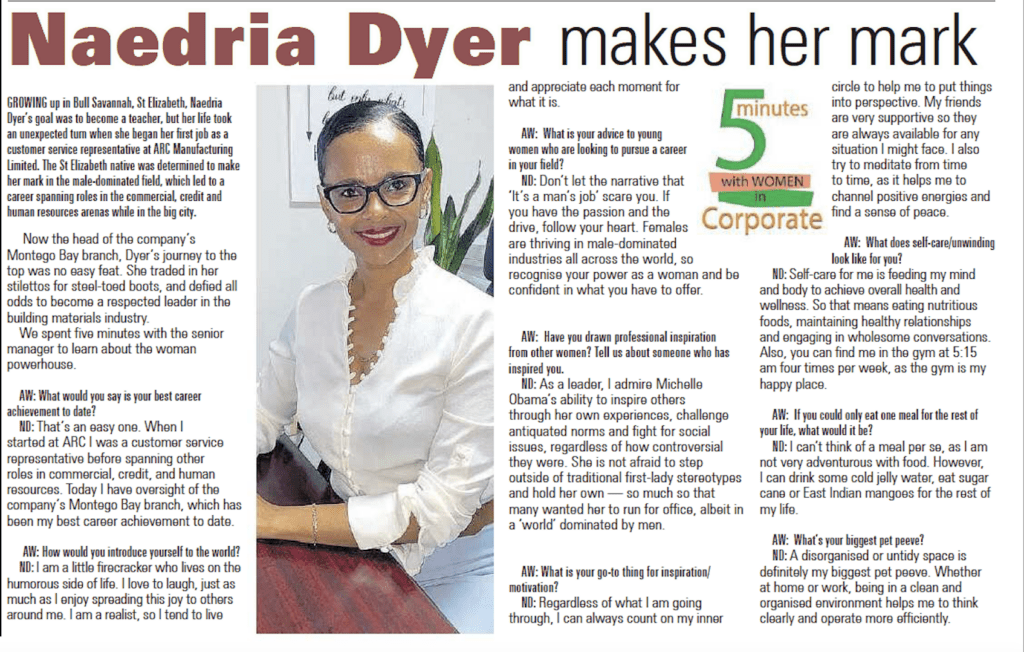

Norman Horne CD, JP, is Executive Chairman of ARC Manufacturing Limited

Published by the Jamaica Observer.