Government Pursuing Programme to Facilitate Trade

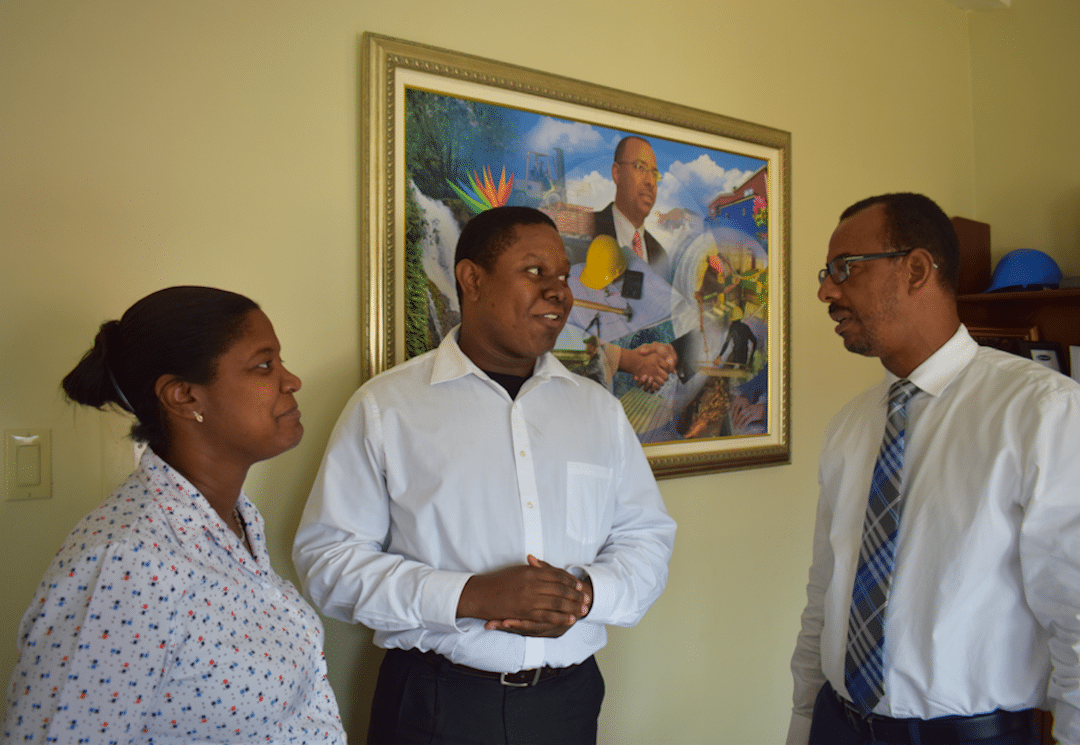

Industry, Commerce, Agriculture and Fisheries Minister, Hon. Audley Shaw, says the Government has commenced a programme of trade facilitation to increase Jamaica’s chances of global competitiveness.

He was speaking at the launch of ARC Manufacturing Limited’s metal slitting plant, at the company’s Bell Road address in Kingston, recently.

“Some weeks ago, the Cabinet approved a number of initiatives to further enhance and facilitate trade, including the elimination of a number of fees and charges that are no longer relevant but have been on the books and people have been collecting,” he said.

Mr. Shaw said this programme seeks to give local manufacturers a competitive advantage. “It cannot be that we are encouraging local value-added manufacturing, but encourage low duty importation of competitor goods. I am going to be focusing on trade facilitation. We have to make it easier for people who want to add value in Jamaica and create jobs and create prosperity in our country,” the Minister emphasized.

Another measure is the recently launched Jamaica Trade Information Portal (JTIP). The portal provides a single authoritative source for trade information relating to import-export regulations, requirements and processes, which businesses can easily access at any time.

Meanwhile, the Minister commended the management of ARC Manufacturing Limited for its state-of-the-art metal slitting plant valued at US$425,000, which he said, will support national development.

Mr. Shaw argued that establishment of the metal slitting plant comes at an opportune time, as with the increased activity in the local construction sector, this service will meet the demands of the manufacturing sector, specifically the building materials industry.

For his part, Executive Chairman, ARC Manufacturing Limited, Norman Horne, pointed out that the plant is the first of its kind in Jamaica, and that investment in the facility seeks to meet the demand of the local manufacturing industry.

“We have invested in two slitters. They both can do the same thing. One is high speed and the other is medium speed. This industry is new to Jamaica. In our country, we don’t have all the dynamics aligned that are ideal for manufacturing; therefore, we have to look to our advantages and try to capitalize on those,” he said.

Metal slitting refers to the process by which metal sheets are fed lengthwise through a slitter machine and cut into narrow coils. It is an essential manufacturing process which is used in the production of essential building materials, including guttering, roofing tiles, barrel capping, purlins, tracks and studs.

Published by The Jamaica Information Service (JIS).